Hydraulic get a grip on valves are important parts in hydraulic techniques, helping as the main element regulators of substance movement, pressure, and direction. These valves perform a crucial position in a wide array of applications, from industrial equipment and construction gear to aerospace and automotive systems. The elementary principle behind hydraulic get a handle on valves is based on their capacity to control the movement of hydraulic water within a program, allowing for precise get a handle on and manipulation of varied components.

One of the primary operates of hydraulic control valves is always to regulate the stress in just a hydraulic system. Force get a handle on valves, such as relief valves, make sure that the stress stays within secure running limits, avoiding possible damage to sensitive and painful components. That is specially essential in applications wherever sustaining a certain force stage is crucial for optimal performance and safety.

Online get a handle on valves are still another crucial sounding hydraulic control valves. These valves determine the path of water movement within the device, allowing the controlled motion of hydraulic actuators. Whether it’s the extension or retraction of a hydraulic cylinder or the turning of a engine, online get a grip on valves govern the trails whereby hydraulic fluid passes, dictating the movement of the connected machinery.

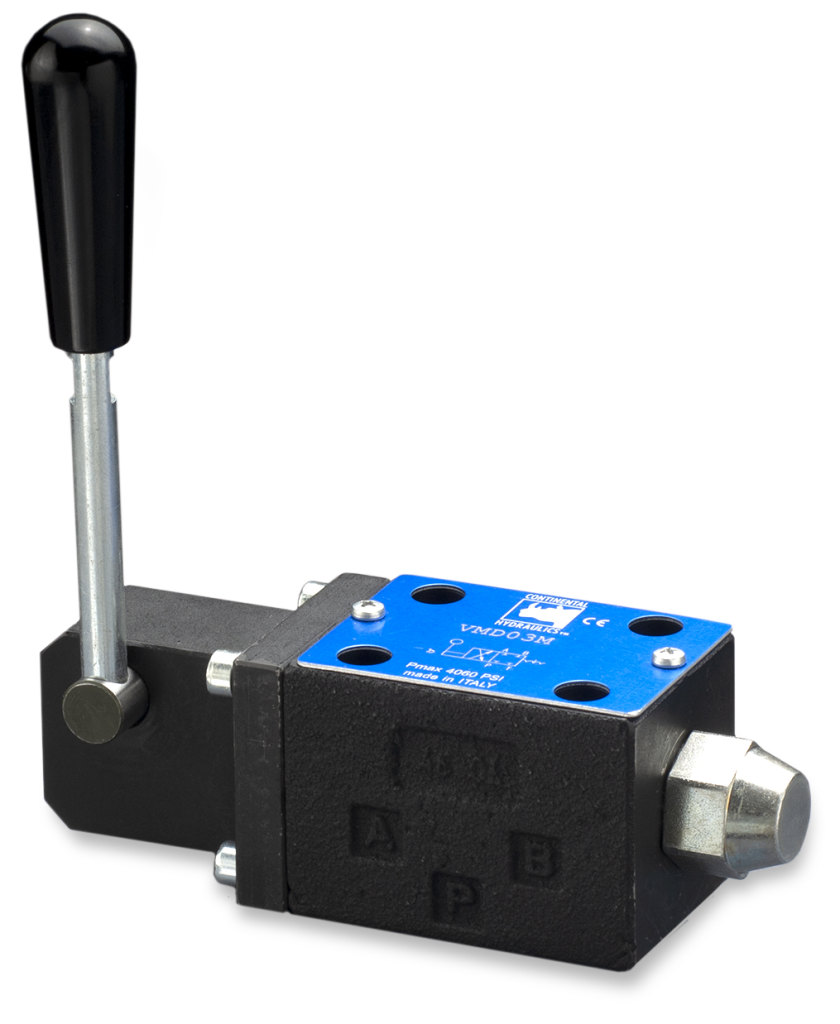

Hydraulic control valves were created with a variety of get a grip on systems, including guide, physical, and electro-hydraulic. Guide valves allow for hands-on control, technical valves react to external allows or mechanical inputs, and electro-hydraulic valves control electric signs for precise and automated control. This diversity in control alternatives makes hydraulic systems versatile to various operational demands and consumer preferences.

Efficiency is just a crucial consideration in hydraulic methods, and hydraulic get a handle on valves play a essential position in optimizing performance. Proportional get a grip on valves, for example, enable fine-tuned adjustments to liquid movement rates, enabling specific control on the speed and power of hydraulic actuators. This degree of get a handle on increases overall program effectiveness, reducing power spend and ensuring optimal operation.

As well as their principal operates, hydraulic control valves donate to process safety. Pressure reduction valves become fail-safes, defending the machine from overpressure and possible damage. The open nature of those valves guarantees that, in the case of a force spike, hydraulic water is diverted properly, blocking catastrophic failures and safeguarding equally the equipment and personnel.

The maintenance of hydraulic control valves is essential for experienced program performance. Standard inspections, washing, and lubrication are necessary to prevent wear and split, escapes, and different issues that might compromise the operation of the valves. Appropriate maintenance not merely extends the lifetime of the valves but additionally assures the reliability of the whole hydraulic system.

Creativity in hydraulic get a handle on valve technology continues to hydraulic motors , with the integration of digital and intelligent technologies. Electronic control units (ECUs) help accurate and programmable control around hydraulic systems, starting paths for automation, remote tracking, and predictive maintenance. As industries move towards Market 4.0, the position of smart hydraulic get a handle on valves becomes increasingly essential in making interconnected and smart hydraulic systems.

In summary, hydraulic control valves will be the unsung heroes of hydraulic programs, providing the mandatory get a grip on and regulation for the successful function of various equipment and equipment. Their versatility, detail, and factor to process safety make sure they are essential in industries where hydraulic power is harnessed for an array of applications. As engineering continues to improve, hydraulic get a handle on valves will likely enjoy a much more advanced position in surrounding the continuing future of hydraulic systems across varied sectors.