Injection molding has revolutionized manufacturing by enabling the mass production of complex and intricate plastic components with unparalleled efficiency. In this article, we explore how injection molding has redefined manufacturing processes, driving innovation and productivity in various industries.

A Manufacturing Game-Changer:

Discuss how injection molding has replaced traditional manufacturing methods for plastic components.

Explain its impact on reducing production costs and cycle times.

The Injection Molding Process:

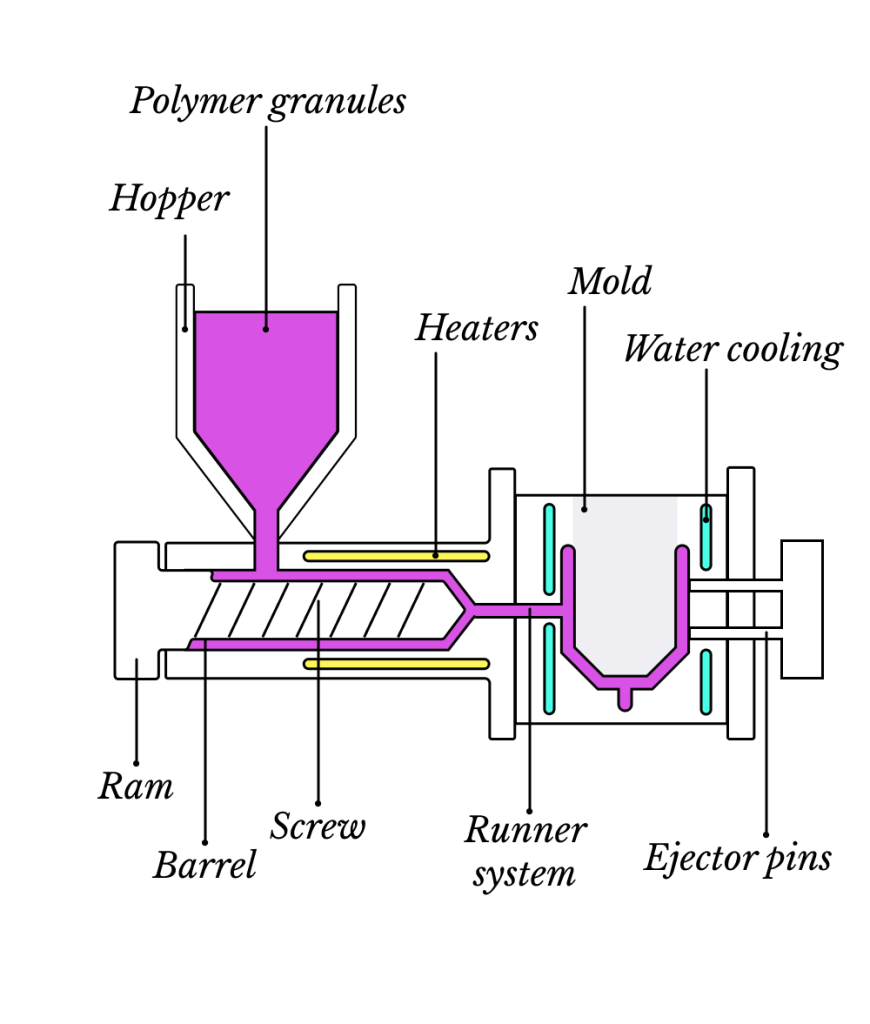

Provide an in-depth overview of the injection molding process, from material selection and melting to injection and cooling.

Explain the importance of precision control in achieving consistent results.

Customization and Versatility:

Explore how injection molding allows for customization through mold design, enabling the creation of unique products.

Highlight its versatility in producing everything from automotive parts to medical devices.

Efficiency in Mass Production:

Discuss how injection molding excels in mass production, producing identical parts with minimal variations.

Explain how automation and robotics have further improved production efficiency.

Quality Assurance:

Emphasize the role of quality control measures, including inspections and statistical process control (SPC), in maintaining product consistency.

Discuss the importance of quality assurance in industries like healthcare and automotive.

Sustainability and Material Efficiency:

Address the growing emphasis on sustainability in injection molding, with a focus on reducing material waste and energy consumption.

Highlight the use of recycled and eco-friendly materials.

Industry-Specific Applications:

Showcase how injection molding has transformed industries, including aerospace, electronics, packaging, and more.

Provide examples of innovative products made possible through vacuum hardening near me molding.

Advanced Technologies and Industry 4.0:

Discuss how advanced technologies, such as 3D printing for mold making and real-time monitoring, are enhancing injection molding processes.

Explore the concept of Industry 4.0 and its integration into injection molding facilities.

Global Impact:

Highlight the global impact of injection molding, both in terms of economic contributions and the availability of affordable products.

Discuss the role of injection molding in driving innovation and competitiveness.

Conclusion:

Injection molding has evolved from a manufacturing technique to a driving force behind efficiency and innovation in various industries. Its ability to produce high-quality, customized parts at scale continues to shape the future of manufacturing, making it a cornerstone of modern industry.